Lisebelisoa tse tala tsa lisebelisoa tse kopaneng li kenyelletsa resin, fiber le lisebelisoa tsa mantlha, jj.Ho na le likhetho tse ngata, 'me thepa e' ngoe le e 'ngoe e na le matla a eona a ikhethang, ho satalla, ho tiea le botsitso ba mocheso,' me litšenyehelo le tlhahiso ea eona le tsona li fapane.

Leha ho le joalo, thepa e kopantsoeng ka kakaretso, ts'ebetso ea eona ea ho qetela ha e amane feela le matrix a resin le likhoele (le thepa ea mantlha ka har'a sebopeho sa sandwich), empa hape e amana haufi-ufi le mokhoa oa moralo le ts'ebetso ea tlhahiso ea thepa ka har'a sebopeho. .

Sengoliloeng sena se tla hlahisa mekhoa e sebelisoang hangata ea ho etsa motsoako, lintlha tse ka sehloohong tse susumetsang mokhoa o mong le o mong le mokhoa oa ho khetha lisebelisoa tse tala bakeng sa lits'ebetso tse fapaneng.

Tlhaloso ea mokhoa:Ts'ebetso ea ho bopa eo lisebelisoa tse matlafalitsoeng tsa fiber e khaotsoeng le sistimi ea resin e fafatsoang ka har'a hlobo ka nako e le 'ngoe, ebe e phekoloa tlas'a khatello e tloaelehileng ho theha sehlahisoa se kopantsoeng sa thermosetting.

khetho ea thepa:

Resin: haholo-holo polyester

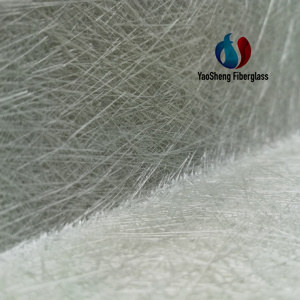

Fiber: khoele ea khalase e mahoashe

Lisebelisoa tsa mantlha: Ha ho na, e hloka ho kopanngoa le laminate ka thoko

Molemo o moholo:

1) Mosebetsi oa matsoho o na le histori e telele

2) Theko e tlase, fiber e potlakileng le ho beha resin

3) Theko e tlaase ea hlobo

Mathata a mantlha:

1) Boto ea laminated e bonolo ho theha sebaka se ntlafalitsoeng sa resin, 'me boima bo batla bo le holimo

2) Ho ka sebelisoa likhoele tse khaotsoeng feela, tse fokotsang haholo thepa ea mochini ea laminate

3) Bakeng sa ho nolofatsa ho fafatsa, viscosity ea resin e hloka ho ba tlase ho lekana ho lahleheloa ke thepa ea mochini le ea mocheso oa thepa e kopaneng.

4) Lintho tse phahameng tsa styrene ka har'a resin ea spray li bolela likotsi tse phahameng tse ka bang teng ho basebelisi, 'me viscosity e tlase e bolela hore resin e bonolo ho kenella liphahlo tsa mosebetsi tsa basebetsi le ho ikopanya le letlalo ka kotloloho.

5) Lekhalo la styrene volatilized moeeng ho thata ho finyella litlhoko tsa molao

ts'ebeliso e tloaelehileng:

Fensetere e bonolo, liphanele tsa sebopeho sa mojaro o tlase joalo ka 'mele oa likoloi tse fetolehang, meketjana ea literaka, libate le likepe tse nyane.

Tlhaloso ea mokhoa:Ka letsoho kenya likhoele ka resin.Likhoele li ka matlafatsoa ka ho loha, ho loha, ho roka kapa ho tlamahanngoa.Ho beha matsoho hangata ho etsoa ka li-rollers kapa li-brushes, ebe resin e petetsoa ka rabara ea rabara hore e kene ka har'a likhoele.Li-laminate li ile tsa phekoloa tlas'a khatello e tloaelehileng.

khetho ea thepa:

Resin: ha ho hlokahale, epoxy, polyester, polyvinyl ester, phenolic resin lia amoheleha.

Fiber: Ha ho hlokahale, empa fiber ea aramid e nang le boima ba 'mele e kholoanyane ho thata ho kenella ka ho beha letsoho.

Lisebelisoa tsa mantlha: ha ho hlokahale

Molemo o moholo:

1) Mosebetsi oa matsoho o na le histori e telele

2) Ho bonolo ho ithuta

3) Haeba mocheso oa kamore o phekola resin e sebelisoa, theko ea hlobo e tlase

4) Khetho e kholo ea lisebelisoa le bafani ba thepa

5) Lifaeba tse phahameng, likhoele tse sebelisoang li telele ho feta mokhoa oa ho fafatsa

Mathata a mantlha:

1) Ho kopanya resin, lihlahisoa tsa resin le boleng ba laminate li amana haufi-ufi le bokhoni ba basebetsi, ho thata ho fumana li-laminate tse nang le lihlahisoa tse tlaase le porosity e tlaase.

2) Likotsi tsa bophelo bo botle le polokeho ea resin.Ha boima ba limolek'hule ba resin e behang letsoho bo le tlase, ho ba le kotsi e kholo ea bophelo bo botle.Ha viscosity e tlase, ho ba bonolo hore resin e kenelle ka har'a liaparo tsa basebetsi ebe e ikopanya le letlalo ka kotloloho.

3) Haeba lisebelisoa tse ntle tsa moea li sa kengoa, ho thata ho fihlela litlhoko tsa molao tsa styrene volatilized ho tloha polyester le polyvinyl ester moeeng.

4) Viscosity ea resin ea ho beha letsoho e lokela ho ba tlase haholo, kahoo litaba tsa styrene kapa li-solvents tse ling li tlameha ho ba tse phahameng, kahoo li lahleheloe ke thepa ea mochine / mocheso oa thepa e kopantsoeng.

Lisebelisoa tse tloaelehileng:mahare a tloaelehileng a turbine ea moea, liketsoana tse hlahisoang ka bongata, mehlala ea meralo

3. Ts'ebetso ea mokotla oa vacuum

Tlhaloso ea mokhoa:Ts'ebetso ea mokotla oa vacuum ke katoloso ea ts'ebetso e boletsoeng ka holimo ea ho beha matsoho, ke hore, lesela la filimi ea polasetiki le tiisitsoe holim'a hlobo ho hloekisa laminate e behiloeng ka letsoho, 'me khatello ea sepakapaka e sebelisoa ho laminate ho finyella. sephetho sa ho felloa ke matla le ho kopana.Ho ntlafatsa boleng ba lisebelisoa tse kopantsoeng.

khetho ea thepa:

Resin: haholo-holo epoxy le phenolic resin, polyester le polyvinyl ester ha li tšoanelehe hobane li na le styrene, e kenang ka har'a pompo ea vacuum.

Fiber: Ha ho hlokahale, esita le likhoele tse nang le boima bo boholo ba motheo li ka kolobisoa tlas'a khatello

Lisebelisoa tsa mantlha: ha ho hlokahale

Molemo o moholo:

1) E ka fihlela litaba tsa fiber tse phahameng ho feta mokhoa o tloaelehileng oa ho beha matsoho

2) Porosity e tlase ho feta mokhoa o tloaelehileng oa ho beha matsoho

3) Tlas'a boemo ba khatello e mpe, phallo e feletseng ea resin e ntlafatsa tekanyo ea ho koloba ha likhoele.Ehlile, karolo ea resin e tla monngoa ke lisebelisoa tsa vacuum

4) Bophelo bo Botle le Tšireletseho: Ts'ebetso ea mokotla oa vacuum e ka fokotsa ho lokolloa ha li-volatile nakong ea phekolo

Mathata a mantlha:

1) Mekhoa e meng e eketsa litšenyehelo tsa basebetsi le lisebelisoa tsa mokotla oa vacuum tse lahliloeng

2) Litlhoko tse phahameng tsa tekheniki bakeng sa basebelisi

3) Taolo ea ho kopanya li-resin le li-resin li itšetlehile haholo ka bokhoni ba motho ea sebetsang

4) Le hoja mokotlana oa vacuum o fokotsa ho lokolloa ha li-volatiles, tšokelo ea bophelo bo botle ho motho ea sebetsang e ntse e phahame ho feta ea infusion kapa prepreg process.

Lisebelisoa tse tloaelehileng:li-yachts tse kholo, tsa nako e le 'ngoe, likarolo tsa koloi ea mabelo, tlamahano ea thepa ea mantlha kahong ea likepe

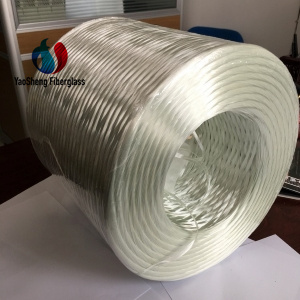

Deyang Yaosheng Composite Material Co., Ltd.ke k'hamphani ea litsebi e hlahisang lihlahisoa tse fapaneng tsa fiber ea khalase.Khampani e hlahisa haholo-holo Fiberglass roving, glass fiber chopped strand mat, glass fiber cloth / roving fabric / marine cloth, joalo-joalo. Ka kopo, ikutloe u lokolohile ho ikopanya le rona.

Mohala: +86 15283895376

Whatsapp: +86 15283895376

Email: yaoshengfiberglass@gmail.com

Tlhaloso ea mokhoa:Ts'ebetso ea matsoelintsoeke e sebelisoa ho etsa likarolo tsa sebopeho se sekoti, se chitja kapa sa oval joalo ka liphaephe le litanka.Ka mor'a hore sephutheloana sa faeba se kenngoe ka resin, se lemetse holim'a mandrel ka litsela tse sa tšoaneng, 'me mokhoa ona o laoloa ke mochine o tsoelipanang le lebelo la mandrel.

khetho ea thepa:

Resin: ha ho hlokahale, joalo ka epoxy, polyester, polyvinyl ester le phenolic resin, joalo-joalo.

Fiber: ha ho hlokahale, sebelisa fiber bundle ea creel ka ho toba, ha ho hlokahale ho loha kapa ho roka ka lesela la fiber.

Lintho tse ka sehloohong: ha ho hlokahale, empa letlalo hangata ke thepa e entsoeng ka lera le le leng

Molemo o moholo:

1) Lebelo la tlhahiso le potlakile, 'me ke mokhoa oa moruo le o utloahalang oa ho beha

2) Likahare tsa resin li ka laoloa ka ho lekanya palo ea resin e tsamaisoang ke sephutheloana sa fiber se fetang ka tanka ea resin.

3) Fokotsa litšenyehelo tsa fiber, ha ho na mokhoa oa ho loha o mahareng

4) Ts'ebetso ea sebopeho e ntle haholo, hobane likhoele tsa likhoele li ka beoa ka litsela tse fapaneng tse jarang moroalo.

Litšitiso tse kholo:

1) Ts'ebetso ena e lekanyelitsoe ho meaho e sekoti e chitja

2) Likhoele ha li bonolo ho hlophisoa ka nepo ho latela tataiso ea axial ea karolo

3) Litsenyehelo tsa hlobo ea mandrel e motona bakeng sa likarolo tse kholo tsa sebopeho li batla li phahame

4) Sebaka se ka ntle sa sebopeho ha se bokaholimo ba hlobo, ka hona botle ba botle bo futsanehile

5) Ha u sebelisa resin e nang le viscosity e tlase, tlhokomelo e lokela ho lefshoa ts'ebetsong ea lik'hemik'hale le ts'ebetso ea bophelo bo botle le polokeho.

Lisebelisoa tse tloaelehileng:litanka tsa polokelo ea lik'hemik'hale le liphaephe tsa ho tsamaisa, li-cylinders, litanka tse phefumolohang tsa litima-mollo

Tlhaloso ea mokhoa:Sephutheloana sa fiber se huloang ho tloha creel se qoelisoa ebe se fetisoa ka poleiti ea ho futhumatsa, 'me resin e kenngoa ka har'a fiber holim'a poleiti ea ho futhumatsa,' me lihlahisoa tsa resin li laoloa, 'me qetellong thepa e phekoloa ka sebōpeho se hlokahalang;sehlahisoa sena se phekotsoeng se entsoeng ka sebopeho se entsoe ka mokhoa o sehiloeng ka bolelele bo fapaneng.Li-fibers li ka boela tsa kenya poleiti e chesang ka litsela tse ling ntle le likhato tse 0.

Pultrusion ke ts'ebetso e tsoelang pele ea tlhahiso, 'me karolo ea sefapano sa sehlahisoa hangata e na le sebopeho se tsitsitseng, se lumellang liphetoho tse nyenyane.Lokisa thepa ea pele ho metsi e fetang ka har'a hot plate 'me u e ale ka har'a hlobo bakeng sa ho fola hang-hang.Le hoja ts'ebetso ena e na le tsoelo-pele e fokolang, e ka fetola sebopeho sa likarolo tse fapaneng.

khetho ea thepa:

Resin: hangata epoxy, polyester, polyvinyl ester le phenolic resin, joalo-joalo.

Fiber: ha ho hlokahale

Lisebelisoa tsa mantlha: ha li sebelisoe hangata

Molemo o moholo:

1) Lebelo la tlhahiso le potlakile, 'me ke mokhoa oa moruo le o utloahalang oa ho kolobisa le ho phekola lisebelisoa.

2) Taolo e nepahetseng ea litaba tsa resin

3) Fokotsa litšenyehelo tsa fiber, ha ho na mokhoa oa ho loha o mahareng

4) Ts'ebetso e ntle ea sebopeho, hobane likhoele tsa fiber li hlophisitsoe ka tsela e otlolohileng mme karoloana ea bophahamo ba fiber e phahame.

5) Sebaka sa ho kenella ha fiber se ka koaloa ka ho feletseng ho fokotsa ho lokolloa ha li-volatiles

Mathata a mantlha:

1) Ts'ebetso ena e fokotsa sebopeho sa likarolo tse fapaneng

2) Theko ea sejana sa ho futhumatsa e batla e phahame

Lisebelisoa tse tloaelehileng:Maballo le literase bakeng sa meaho ea matlo, marokho, litepisi le terata

6. Resin Transfer Molding (RTM)

Tlhaloso ea mokhoa:Beha likhoele tse omeletseng ka har'a hlobo e tlase, sebelisa khatello esale pele ho etsa hore likhoele li lumellane le sebopeho sa hlobo ka hohle kamoo ho ka khonehang, 'me u li tlame;ebe, lokisa hlobo e ka holimo ka hlobo e ka tlaase ho etsa sekoti, ebe o kenya resin ka mokoting oa hlobo.

Hangata ho sebelisoa ente e thusang resin ea vacuum le ho kenella ha likhoele, e leng vacuum assisted resin infusion process (VARI).Hang ha ho kenngoa ha fiber ho phethiloe, valve ea kenyelletso ea resin ea koaloa 'me motsoako oa phekoloa.Ente ea resin le pheko e ka etsoa ka mocheso oa kamore kapa tlas'a maemo a futhumetseng.

khetho ea thepa:

Resin: hangata epoxy, polyester, polyvinyl ester le phenolic resin, bismaleimide resin e ka sebelisoa ka mocheso o phahameng.

Fiber: Ha ho hlokahale.Likhoele tse rokiloeng li loketse ts'ebetso ena hobane likheo tsa fiber bundle li thusa ho fetisa resin;ho na le likhoele tse ntlafalitsoeng ka ho khetheha ho nolofatsa phallo ea resin

Lintho tse ka sehloohong: Foam ea khekhe ea linotsi ha e tšoanelehe, hobane lisele tsa khekhe ea linotsi li tla tlala resin, 'me khatello e tla etsa hore foam e oele.

Molemo o moholo:

1) Karolo e phahameng ea fiber volume le porosity e tlase

2) Kaha resin e tiisitsoe ka botlalo, e phetse hantle ebile e bolokehile, 'me tikoloho ea ts'ebetso e hloekile ebile e makhethe.

3) Fokotsa tšebeliso ea basebetsi

4) Mahlakore a ka holimo le a ka tlaase a karolo ea mohaho ke libaka tsa hlobo, tse bonolo bakeng sa phekolo e latelang ea holim'a metsi.

Litšitiso tse kholo:

1) Hlobo e sebelisoang hammoho e theko e boima, 'me e le ho mamella khatello e kholoanyane, e boima ebile e batla e le boima.

2) E lekanyelitsoe ho etsoa ha likarolo tse nyane

3) Libaka tse se nang metsi li atisa ho hlaha, e leng se etsang hore ho be le likhahla tse ngata

Lisebelisoa tse tloaelehileng:sepakapaka se senyenyane le se rarahaneng le likarolo tsa likoloi, litulo tsa terene

7. Mekhoa e meng ea perfusion - SCRIMP, RIFT, VARTM, joalo-joalo.

Tlhaloso ea Mokhoa:Beha likhoele tse omeletseng ka mokhoa o ts'oanang le ts'ebetso ea RTM, ebe o beha lesela la tokollo le letlooa la drainage.Ka mor'a hore moralo o phethoe, o tiisitsoe ka ho feletseng ka mokotla oa vacuum, 'me ha sekheo se fihla ho tlhokahalo e itseng, resin e kenngoa mohahong oohle oa layup.Kabo ea resin ka laminate e finyelloa ka ho tataisa resin e phallang ka letlooa la tataiso, 'me qetellong likhoele tse omeletseng li kenngoa ka ho feletseng ho tloha holimo ho ea tlaase.

khetho ea thepa:

Resin: hangata epoxy, polyester, polyvinyl ester resin

Fiber: Fiber leha e le efe e tloaelehileng.Likhoele tse roketsoeng li loketse tšebetso ena hamolemo kaha likheo tsa fiber bundle li potlakisa phetiso ea resin

Lisebelisoa tsa mantlha: foam ea khekhe ea linotsi ha e sebetse

Molemo o moholo:

1) Ho tšoana le ts'ebetso ea RTM, empa lehlakore le le leng feela ke bokaholimo ba hlobo

2) Lehlakore le leng la hlobo ke mokotla oa vacuum, o bolokang haholo litšenyehelo tsa hlobo mme o fokotsa tlhokahalo ea hore hlobo e khone ho mamella khatello.

3) Likarolo tse kholo tsa meralo le tsona li ka ba le karoloana e phahameng ea molumo oa fiber le porosity e tlase

4) Mokhoa o tloaelehileng oa mokhoa oa ho beha matsoho o ka sebelisoa bakeng sa ts'ebetso ena ka mor'a ho fetoloa

5) Sebopeho sa sandwich se ka bōptjoa ka nako e le 'ngoe

Mathata a mantlha:

1) Bakeng sa mehaho e meholo, mokhoa ona o batla o le thata, 'me ho lokisoa ho ke ke ha qojoa

2) The viscosity ea resin e tlameha ho ba tlase haholo, e leng ho fokotsang thepa ea mechine

3) Libaka tse se nang metsi li atisa ho hlaha, e leng se etsang hore ho be le likhahla tse ngata

Lisebelisoa tse tloaelehileng:Tlhahiso ea liteko tsa likepe tse nyane, liphanele tsa 'mele bakeng sa literene le literaka, li-blades tsa turbine tsa moea

8. Prepreg - mokhoa oa autoclave

Tlhaloso ea mokhoa:Lesela la fiber kapa lesela le kenngoa pele ke moetsi oa thepa ka resin e nang le mokelikeli, 'me mokhoa oa ho etsa lihlahisoa ke mocheso o phahameng le mokhoa o phahameng oa khatello kapa mokhoa oa ho qhibiliha ha solvent.The catalyst ke latent mocheso oa kamoreng, ho fana ka thepa bophelo ba sethala sa libeke kapa likhoeli mocheso oa kamore;sehatsetsing se ka lelefatsa sethala sa bophelo ba sona.

Prepreg e ka beoa ka letsoho kapa mochini holim'a hlobo, ebe e koaheloa ka mokotla oa vacuum ebe e futhumatsoa ho 120-180 ° C.Ka mor'a ho futhumatsa resin e ka phalla hape 'me qetellong ea folisa.Autoclave e ka sebelisoa ho kenya khatello e eketsehileng ho thepa, hangata ho fihlela ho 5 atmospheres.

khetho ea thepa:

Resin: hangata epoxy, polyester, phenolic resin, resin e hanyetsanang le mocheso o phahameng joalo ka polyimide, cyanate ester le bismaleimide le eona e ka sebelisoa.

Fiber: Ha ho hlokahale.Fiber bundle kapa lesela la fiber le ka sebelisoa

Lintho tse ka sehloohong: ha ho hlokahale, empa foam e hloka ho hanyetsa mocheso o phahameng le khatello e phahameng

Molemo o moholo:

1) Karo-karolelano ea resin ho moemeli ea phekolang le lihlahisoa tsa resin li behiloe ka nepo ke mofani oa thepa, ho bonolo haholo ho fumana li-laminate tse nang le fiber e ngata le porosity e tlase.

2) Thepa e na le litšobotsi tse ntle tsa bophelo bo botle le polokeho, 'me tikoloho ea ho sebetsa e hloekile, e ka boloka litšenyehelo tsa boiketsetso le tsa basebetsi.

3) Litšenyehelo tsa likhoele tsa thepa e sa sebetseng li ea fokotseha, 'me ha ho na ts'ebetso e mahareng e hlokahalang ho loha likhoele lesela.

4) Ts'ebetso ea tlhahiso e hloka resin e nang le viscosity e phahameng le mongobo o motle, hammoho le thepa e ntlafalitsoeng ea mochini le mocheso.

5) Ho atolosoa ha nako ea ho sebetsa mochesong oa kamore ho bolela hore ntlafatso ea sebopeho le moralo oa libopeho tse rarahaneng le tsona li bonolo ho li fihlela.

6) Poloko e ka bang teng ho li-automation le litšenyehelo tsa basebetsi

Mathata a mantlha:

1) Theko ea thepa e eketseha, empa e ke ke ea qojoa e le hore e finyelle litlhoko tsa kopo

2) Ho hlokahala autoclave ho phethela pheko, e nang le litšenyehelo tse phahameng, nako e telele ea ts'ebetso le lithibelo tsa boholo

3) hlobo e hloka ho mamella mocheso o phahameng oa ts'ebetso, 'me thepa ea mantlha e na le litlhoko tse tšoanang

4) Bakeng sa likarolo tse teteaneng, ho hlokahala pre-vacuum ha u beha li-prepregs ho felisa li-bubble tsa moea tse ka hare.

Lisebelisoa tse tloaelehileng:likarolo tsa sebopeho sa sepakapaka (joalo ka mapheo le mehatla), likoloi tsa mabelo tsa F1

9. Prepreg - mokhoa o seng oa autoclave

Tlhaloso ea mokhoa:Mocheso o tlase oa ho phekola prepreg process process o ts'oana hantle le autoclave prepreg, phapang ke hore thepa ea lik'hemik'hale ea resin e lumella hore e phekolehe ho 60-120 ° C.

Bakeng sa pholiso ea mocheso o tlase oa 60 ° C, nako ea ho sebetsa ea thepa ke beke e le 'ngoe feela;bakeng sa li-catalyst tse phahameng tsa mocheso (> 80 ° C), nako ea ho sebetsa e ka fihla likhoeli tse 'maloa.Mokelikeli oa sistimi ea resin o lumella ho phekola ho sebelisa mekotla ea vacuum feela, ho qoba ts'ebeliso ea li-autoclaves.

khetho ea thepa:

Resin: Hangata ke epoxy resin feela

Fiber: ha ho hlokahale, ho tšoana le prepreg ea setso

Lintho tse ka sehloohong: ha ho hlokahale, empa tlhokomelo e khethehileng e lokela ho lefshoa ha u sebelisa foam e tloaelehileng ea PVC

Molemo o moholo:

1) E na le melemo eohle ea prepreg ea setso ea autoclave ((i.))-((vi.))

2) Thepa ea hlobo e theko e tlaase, joalo ka lehong, hobane mocheso oa ho folisa o tlase

3) Ts'ebetso ea ho etsa likarolo tse kholo tsa sebopeho e nolofalitsoe, ho hlokahala feela ho hatella mokotla oa vacuum, ho potoloha moea o chesang oa ontong kapa sistimi e futhumatsang ea moea o chesang oa hlobo ka boeona ho fihlela litlhoko tsa pholiso.

4) Lisebelisoa tse tloaelehileng tsa foam li ka boela tsa sebelisoa, 'me mokhoa ona o hōlile haholoanyane

5) Ha ho bapisoa le autoclave, tšebeliso ea matla e tlase

6) Theknoloji e tsoetseng pele e netefatsa ho nepahala ha maemo le ho pheta-pheta

Mathata a mantlha:

1) Theko ea thepa e ntse e phahame ho feta fiber e omileng, leha litšenyehelo tsa resin li le tlase ho feta prepreg ea aerospace

2) hlobo e hloka ho mamella mocheso o phahameng ho feta ts'ebetso ea infusion (80-140 ° C)

Lisebelisoa tse tloaelehileng:matla a phahameng a tšebetso ea turbine ea moea, likepe tse kholo tsa mabelo le likepe, lifofane tsa pholoso, likarolo tsa terene

10. Non-autoclave process ea semi-preg SPRINT/beam prepreg SparPreg

Tlhaloso ea mokhoa:Ho thata ho ntša li-bubble tsa moea pakeng tsa lihlopha kapa lihlopha tse pota-potileng nakong ea phekolo ha u sebelisa prepreg ka mehaho e teteaneng (> 3mm).E le ho hlōla bothata bona, pele ho vacuumization e ile ea kenngoa ts'ebetsong ea layering, empa Haholo-holo e ile ea eketseha nako ea ts'ebetso.

Lilemong tsa morao tjena, Gurit e hlahisitse letoto la lihlahisoa tse ntlafetseng tsa prepreg tse nang le theknoloji e nang le tokelo ea molao, e leng ho nolofalletsang ho etsoa ha boleng ba boleng bo phahameng (bo tlase ba porosity) li-laminates tse teteaneng ho phethoa ka mohato o le mong.Semi-preg SPRINT e entsoe ka mekhahlelo e 'meli ea faeba e ommeng e kopanyang karolo ea sebopeho sa sandwich ea filimi ea resin.Ka mor'a hore thepa e kenngoe ka har'a hlobo, pompo ea vacuum e ka ntša moea ka ho feletseng ho eona pele resin e chesa le ho nolofatsa le ho kolobisa fiber.tiisitsoe.

Beam prepreg SparPreg ke prepreg e ntlafetseng eo, ha e phekoloa ka tlas'a vacuum, e ka tlosang li-bubble tsa moea habonolo linthong tse kopantsoeng tse peli.

khetho ea thepa:

Resin: hangata epoxy resin, li-resin tse ling le tsona lia fumaneha

Fiber: ha ho hlokahale

Lintho tse ka sehloohong: boholo, empa tlhokomelo e khethehileng e lokela ho lefshoa mocheso o phahameng ha o sebelisa foam e tloaelehileng ea PVC

Molemo o moholo:

1) Bakeng sa likarolo tse teteaneng (100mm), karoloana e phahameng ea fiber volume le porosity e tlase e ntse e ka fumanoa ka nepo.

2) Boemo ba pele ba sistimi ea resin bo tiile, 'me ts'ebetso e ntle haholo kamora ho folisoa ha mocheso o phahameng

3) Lumella tšebeliso ea lesela la faeba la theko e tlase (joalo ka 1600 g/m2), eketsa lebelo la ho beha, le ho boloka litšenyehelo tsa tlhahiso.

4) Ts'ebetso e tsoetse pele haholo, ts'ebetso e bonolo 'me litaba tsa resin li laoloa ka nepo

Mathata a mantlha:

1) Theko ea thepa e ntse e phahame ho feta fiber e omileng, leha litšenyehelo tsa resin li le tlase ho feta prepreg ea aerospace

2) hlobo e hloka ho mamella mocheso o phahameng ho feta ts'ebetso ea infusion (80-140 ° C)

Lisebelisoa tse tloaelehileng:li-blade tsa moea tse sebetsang hantle haholo, likepe tse kholo tsa mabelo le likepe, lifofane tsa pholoso

Nako ea poso: Dec-13-2022